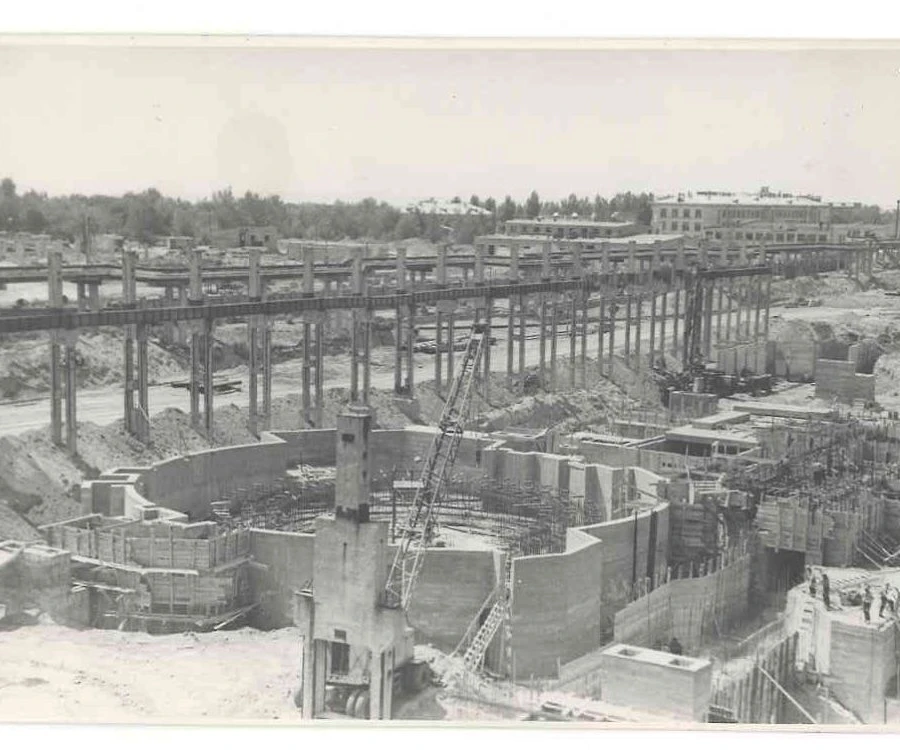

New lines for finishing line pipes were launched.

Manufacturing Tubular Products

Interpipe Niko Tube (Nikopol, Ukraine)

Interpipe Niko Tube (Dnipro)

Interpipe NMPP

Interpipe Niko Tube (Nikopol, Ukraine)

Nikopol, Ukraine

https://nikotube.interpipe.biz

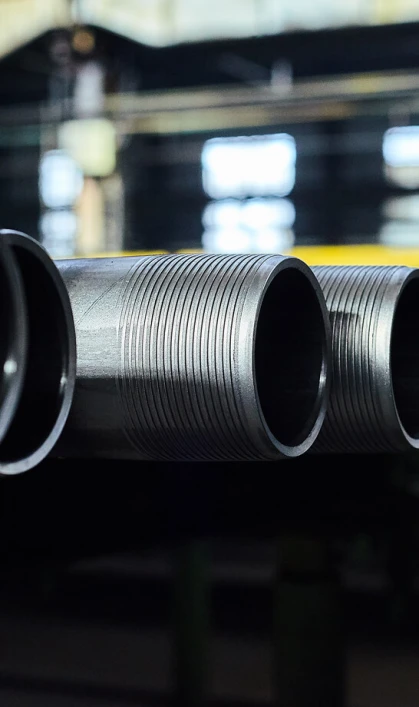

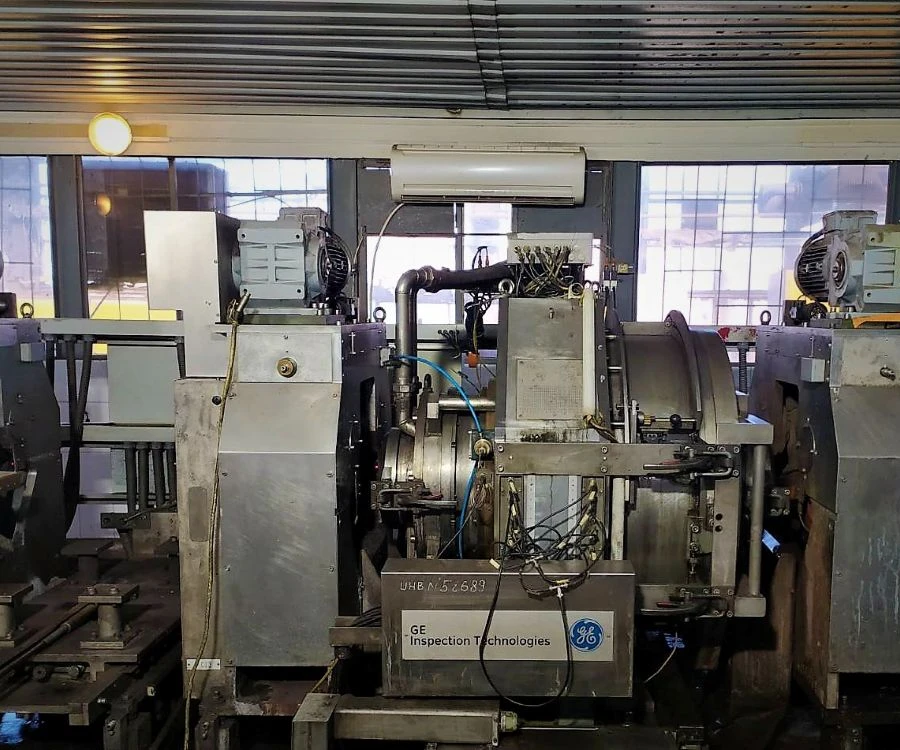

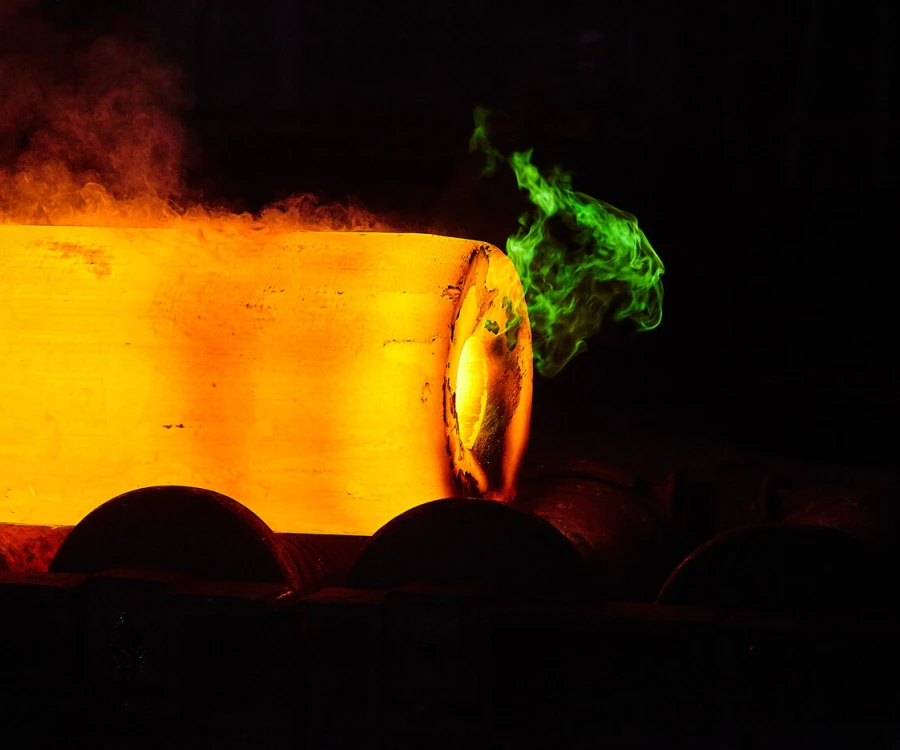

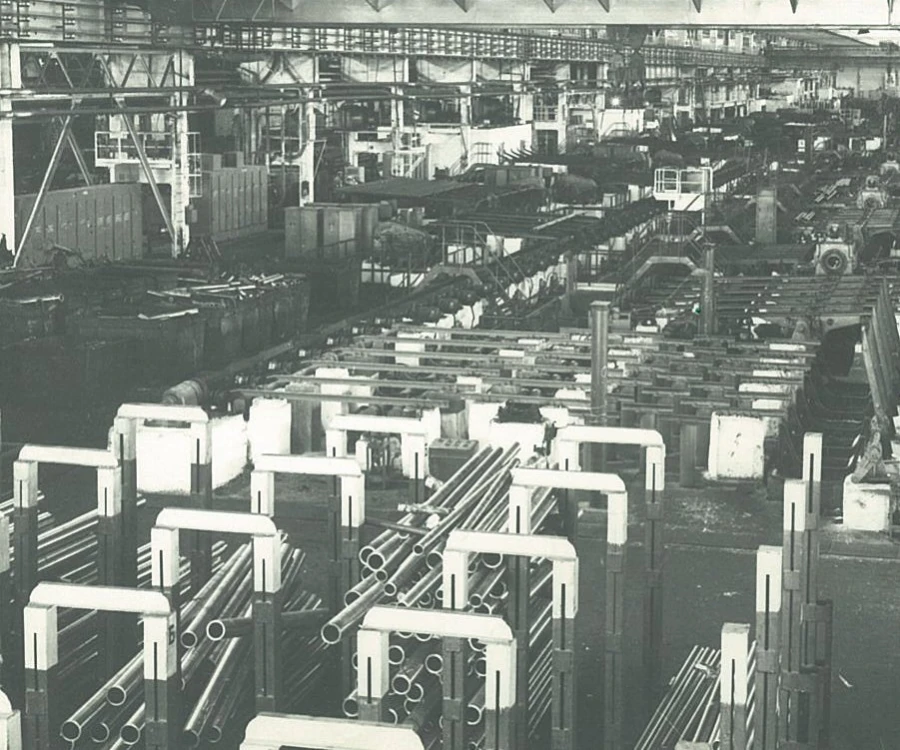

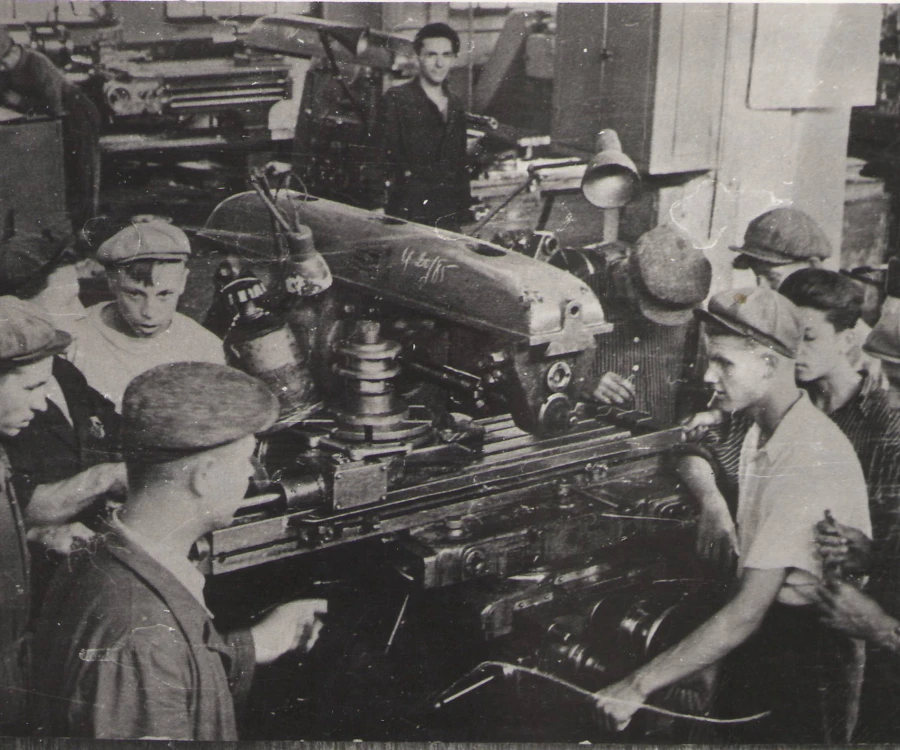

Interpipe Niko Tube (Nikopol, Ukraine) is a major producer of seamless steel pipes for construction, mechanical engineering, oil and gas and energy industries. The production complex comprises 3 main workshops and 2 pipe rolling units, such as one with continuous rolling mills and one with an automatic plug mill. The workshops are equipped with modern finishing lines and facilities that allow applying UV coating, marking and quality control of products in accordance with international standards, using various control methods, such as non-destructive testing, spectral analysis, hydraulic testing, etc.

The Interpipe Niko Tube's (Nikopol) product range includes the following:

Pipes for the oil and gas industry

(diameter 42.0–114.3 mm, wall thickness 4.8–9.5 mm):

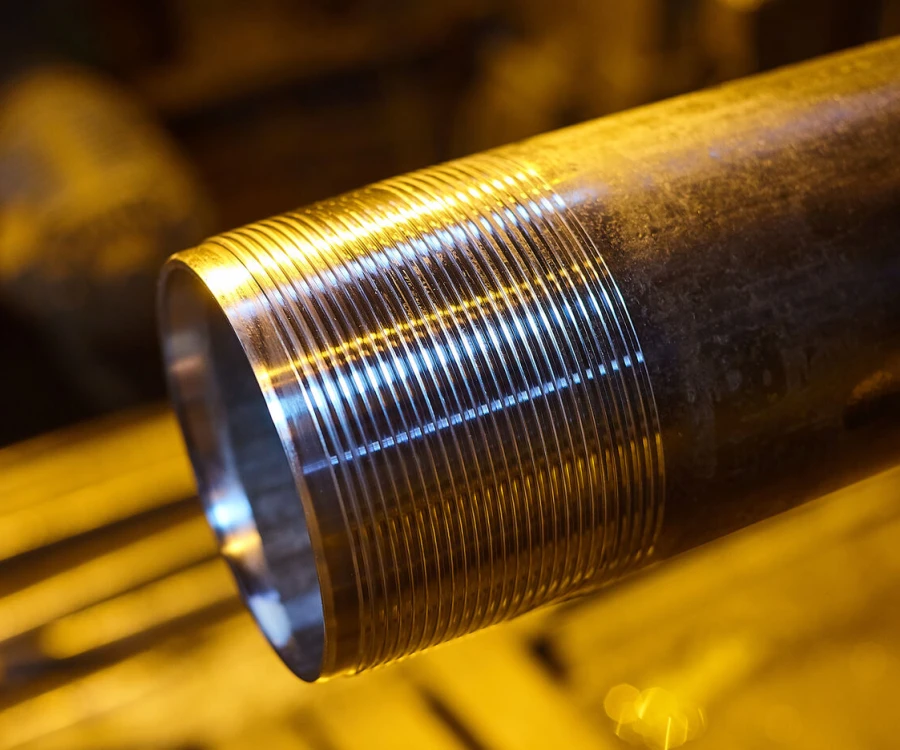

- Compressor pump pipes: smooth, with outward-facing ends, and highly sealed, with premium threaded connections

- Casing and core pipes

- Geology prospecting pipes

- Drilling pipes

- Short pipe adapters

Pipes for mechanical engineering and the energy industry

(diameter 32.0–325.0 mm, wall thickness 2.6–45.0 mm)

- Special purpose pipes

- Boiler pipes

General purpose pipes

(diameter 21.0–325.0 mm, wall thickness 2.0–45.0 mm)

- Line pipes

- Pipes for construction

Interpipe Niko Tube (Dnipro)

Dnipro, Ukraine

https://nikotube.interpipe.biz

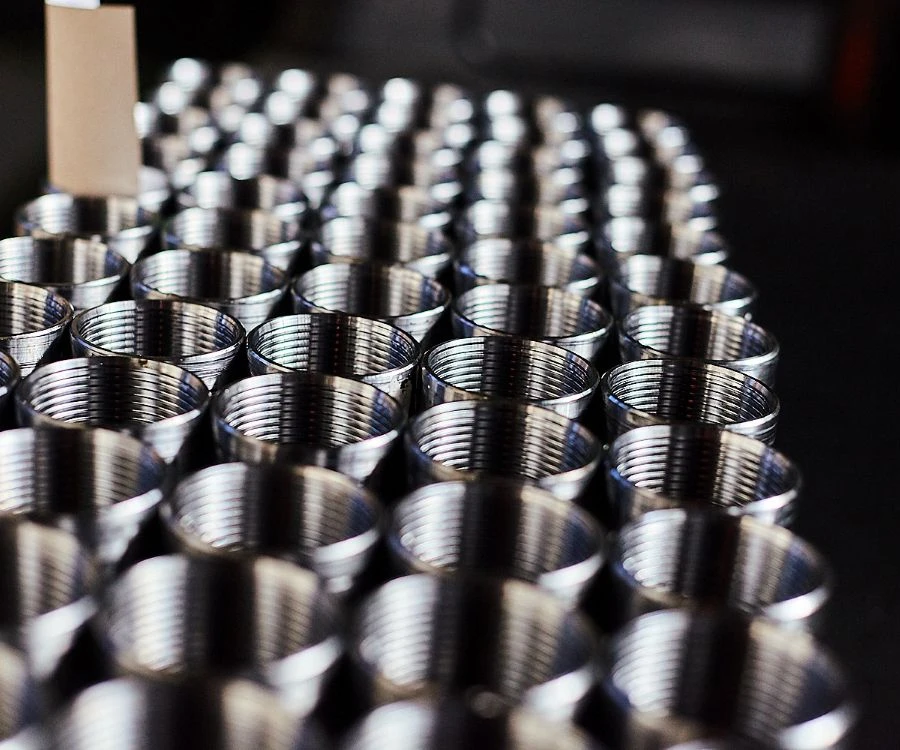

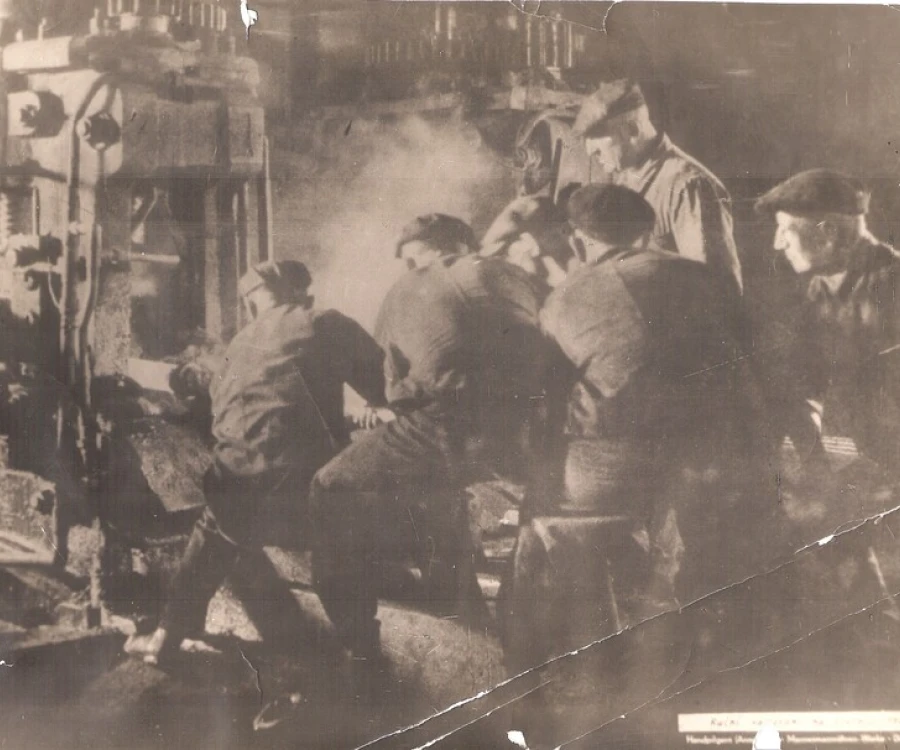

Interpipe Niko Tube (Dnipro) is a major manufacturer of seamless steel pipes for the oil and gas, oil refining, petrochemical, mechanical engineering and energy industries. The main production takes place in 3 pipe-rolling workshops with an automatic plug mill, a pilger mill, an Assel mill and a cold-forming mill. The workshops have equipment for finishing operations and pipe processing, as well as non-destructive and hydraulic testing. There is also a pipe threading shop specialising in finishing operations for oil and gas pipes. The workshop has modern Danobat pipe and coupling cutting lines and a retrofited heat treatment unit for pipe processing.

The Interpipe Niko Tube's (Dnipro) product range includes the following:

Pipes for the oil and gas industry

(diameter 34.0–426.0 mm, wall thickness 8.0–70.0 mm):

- casing

- casing pipe couplings

- short adapters

Pipes for mechanical engineering and the energy industry

(diameter 32.0–426.0 mm, wall thickness 3.0–70.0 mm):

- pipes for PEN and PED

- ball bearing pipes

- precision pipes

Line and general purpose pipes

(diameter 32.0–426.0 mm, wall thickness 3.0–75.0 mm)

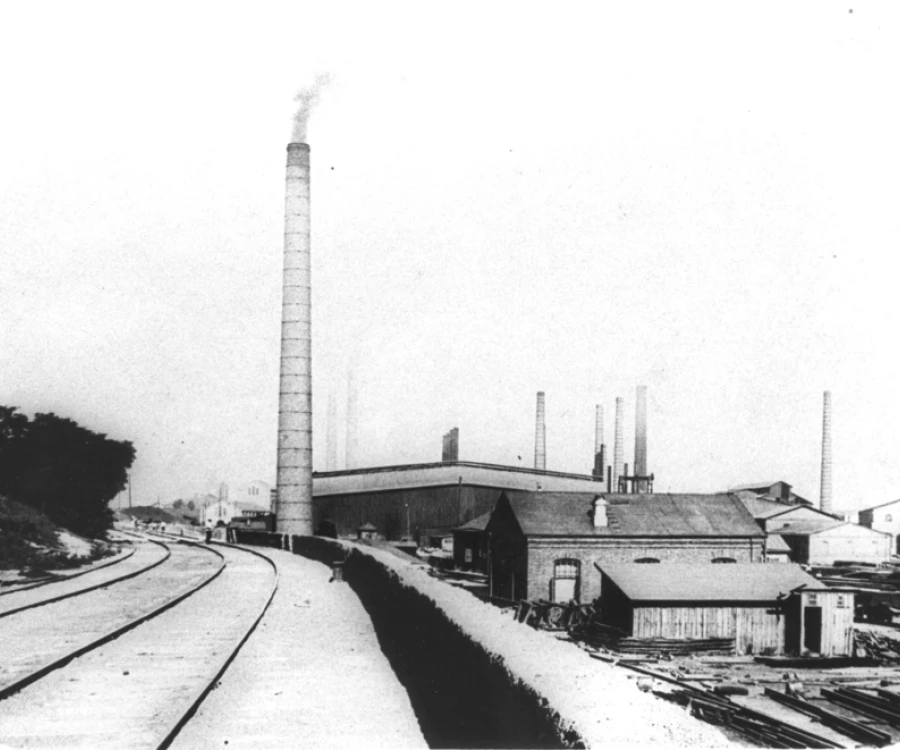

Interpipe NMPP

Samar (Novomoskovsk), Ukraine

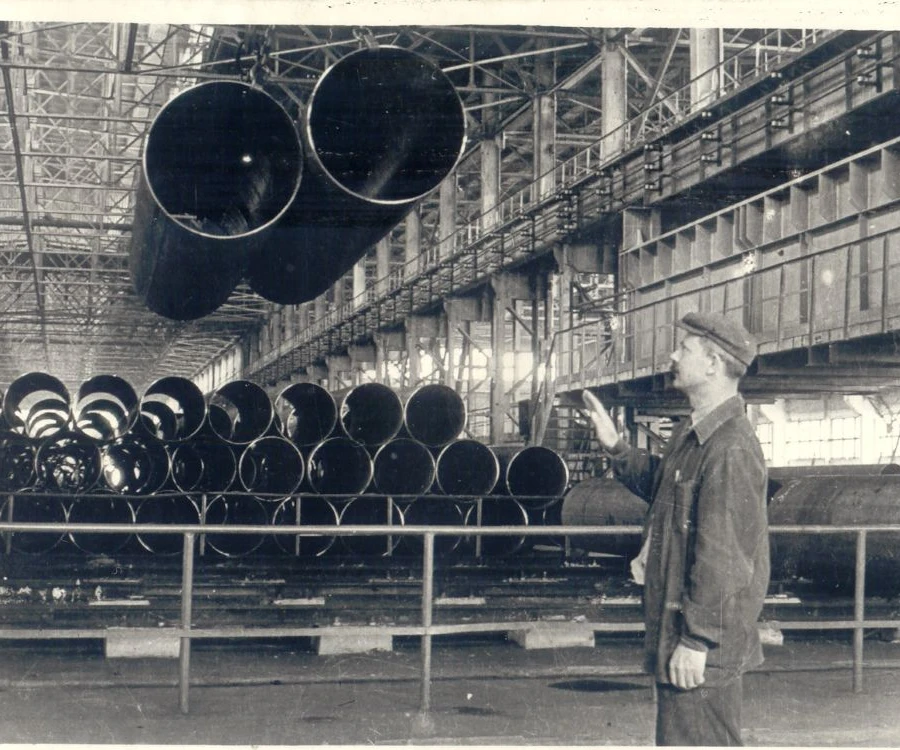

Interpipe NMPP is a manufacturer of electric-welded steel pipes made by submerged arc welding and high-frequency induction welding. The enterprise produces pipes for the construction and oil and gas industries, as well as pipes with insulating coatings.

The Interpipe NMPP's product range includes the following:

- medium-sized pipes (152–530 mm)

- small-gauge pipes (21.3–114.3 mm) made of carbon steel grades

- shaped pipes, 17x17 – 100x80 mm

- anti-corrosion coating of the outer surface of steel pipes (insulation) with a diameter of 114.3–530 mm