As global energy exploration advances into more challenging environments, the demand for reliable and high-performance OCTG remains consistently high. Within this landscape, Interpipe, a global producer of steel pipes headquartered in Ukraine, has established itself as a trusted technology partner for oil and gas companies. Interpipe’s products are used in a third of all buildings across Dubai, while its premium OCTG solutions support the drilling operations for major players like ADNOC.

In this interview, Artem Artemov, MENA Sales Director at Interpipe, looks back on two decades of the company’s presence in the region – from milestone infrastructure projects to pioneering partnerships in the energy sector.

- Interpipe has been active in the MENA market for twenty years. Tell us about this journey.

Indeed, we’ve been operating and developing partnerships with the key market players since the early 2000s and still see the region as full of opportunities. Our early success came through the large-scale civil construction projects, helping us to establish a reputation as a reliable supplier. As an OCTG manufacturer, we’ve expanded into the energy sector over time, securing long-term direct contracts with national oil and gas companies such as ADNOC and QatarEnergy. Now, we continue to prove the efficiency and durability of our tubular solutions.

- The markets you operate in are highly competitive. What are Interpipe’s key advantages?

Our main advantage is a vertically integrated business structure. It gives us consistent quality control across every stage — from scrap collection and recycling to finished tubular products, allows for cost efficiency and operational flexibility that is essential to meet customer expectations. Interpipe continuously invests in modernization and production capacity. The recently completed new heat treatment facility construction, totaling around $27 mln investments, will allow us to increase OCTG output and deliver even more complex solutions.

- What are the key pillars of your strategy in the Middle East?

Localization is a major trend across the region, and Interpipe is ready to deliver. We combine a flexible supply chain with strategic partnerships that support local value creation. Our proximity to the end users allows us to quickly adapt our product line to the needs of a specific market. We’ve demonstrated stable deliveries to our partners in Qatar, Abu Dhabi, and Iraq and see the opportunity to continue growing together.

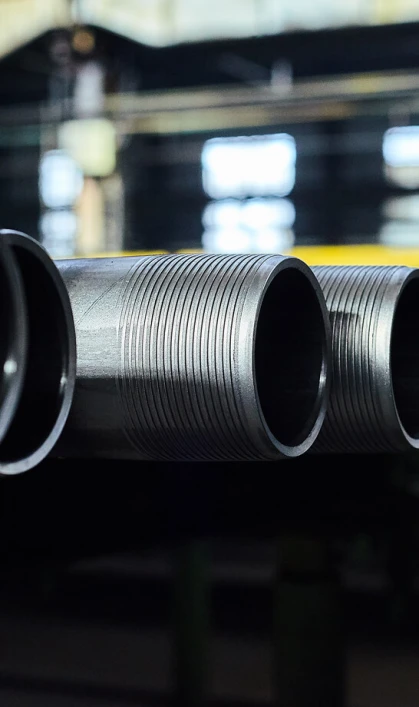

To meet the growing demand of the energy sector, Interpipe developed a UPJ line of premium and semi-premium threaded connections for seamless casing and tubing. Designed for deep and complex wells, these products ensure safe and robust operations under high formation pressures and elevated temperatures, outperforming traditional threads like Buttress.

Certified under ISO 13679 CAL IV UPJ-F and UPJ-M premium solutions meet the highest industry requirements and demonstrate high reliability in wells across the Middle East, Turkey, the USA, CIS and Ukraine.

- The EU is actively finalizing the CBAM regulatory framework. How prepared is Interpipe?

We’re well prepared. Interpipe’s environmental performance already meets the strictest global standards. In 2024 Interpipe reduced specific CO2 emissions per ton of seamless pipes by 61% compared to 2010 levels. By 2030, Interpipe aims to reduce specific CO₂ emissions per ton of seamless pipes by a further 26%.

Our low carbon footprint is achieved through in-house electric steel production and the use of low-carbon electricity. In addition, closed-loop water systems and advanced gas cleaning technologies allow us to minimize our environmental impact.

- What Interpipe focused on at ADIPEC this year?

At ADIPEC, our focus was on showcasing our premium OCTG solutions and tailored pipe products for the Middle East energy sector. We see the exhibition as a valuable platform for strengthening partnerships, engaging with key stakeholders, and exploring new opportunities for collaboration. As the industry moves toward greater efficiency and localization, Interpipe stays committed to supporting this transition with proven technology, reliable supply and trusted expertise.

- Ali&Sons has signed a MOU with Interpipe at ADIPEC. Tell us please more details about this.

Indeed, at ADIPEC-2025, Ali & Sons Oilfield Supplies & Services (ASOS) signed a Memorandum of Understanding (MoU) with Interpipe on technical alliance. Within this partnership Interpipe will provide ASOS with technology, process and best practices enabling it to expand seamless pipe production capacities in Abu Dhabi.

In the near future, ASOS intends to proceed with the practical implementation of greenfield project to build a new integrated pipe solutions complex. This facility located in Abu Dhabi will span 200,000 m2 with an annual capacity of 250,000 MT of seamless pipes to meet the increasing demand in the MENA region and beyond.