Energy Industry Solutions Mechanical Engineering Solutions Pipes for construction and general use Manufacturing Tubular Products Network of warehouses in Ukraine Customer Community Marketing Materials & Catalogues Projects Contacts (tubular products) Certificates

"Interpipe Niko Tube" LLC (Nikopol) Certificates

"Interpipe Niko Tube" LLC (Dnipro) Certificates JSC INTERPIPE NMPP

"Interpipe Niko Tube" LLC (Nikopol) Certificates

"Interpipe Niko Tube" LLC (Dnipro) Certificates JSC INTERPIPE NMPP

Energy Industry Solutions Mechanical Engineering Solutions Pipes for construction and general use Manufacturing Tubular Products Network of warehouses in Ukraine Customer Community Marketing Materials & Catalogues Projects Contacts (tubular products) Certificates

"Interpipe Niko Tube" LLC (Nikopol) Certificates

"Interpipe Niko Tube" LLC (Dnipro) Certificates JSC INTERPIPE NMPP

"Interpipe Niko Tube" LLC (Nikopol) Certificates

"Interpipe Niko Tube" LLC (Dnipro) Certificates JSC INTERPIPE NMPP

Main Media

Media

News

13 February 2026

10 February 2026

23 January 2026

16 January 2026

09 January 2026

08 January 2026

KLW engineered new ULT design for a green steel mill in northern Sweden

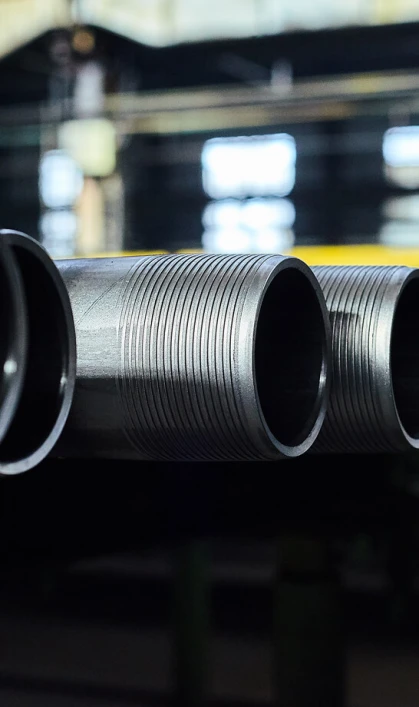

Interpipe developed a new niche product for the oil&gas industry

KLW fully complies with the standards of the Association of American Railroads

Interpipe has secured a year-long contract for an Italian infrastructure project

KLW upgrades traction rolling-stock in Central Asia with new loco wheel designs

Interpipe supplies OCTG pipes for geothermal project in Slovakia

76

76 INTERPIPE in the media

12 November 2025

07 November 2025

27 October 2025

Interpipe bets on complex products and finding new niches, - CPRO Vitaliy Suyeta about product strategy

How Ukrainian company Interpipe elevating the energy industry with proprietary premium solutions

Sales on paper: why Ukrainian Railways’ scrap shipments fell to a 7-year low

7

7 Media contacts:

- Press Officer

Andriy Pysarevsky

- contacts

Mob.: +380 67 952 17 62

- Follow us

Media

Marketing Materials

Corporate brand

"Bank" with corporate materials:

official names, logos,

brand book (instructions for use)