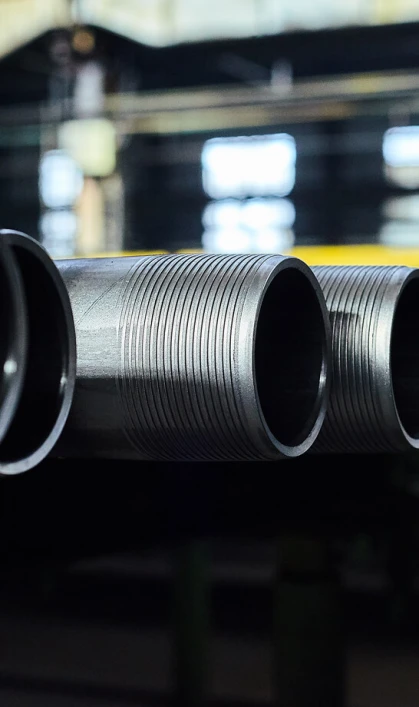

Interpipe produces high-quality round steel billets that meet the requirements of international standard ISO 14-1-235-91.

The billets are supplied without surface treatment (turning and peeling), in unmeasured, measured and multiple measured lengths within the following ranges:

– diameters from 150 mm to 290 mm: from 6.0 m to 11.7 m inclusive

– diameters from 385 mm to 470 mm: from 5.4 m to 9.85 m inclusive

The company produces steel billets for various applications: manufacturing pipes, railway wheels, parts for the energy sector and general mechanical engineering.

Round steel billets for further production of seamless pipes for the oil and gas, machine-building and construction industries, as well as fittings and flanges.

| ANSI API 5L/ISO 3183

ASTM A53

ASTM A106 | A, B, C | Line Pipe Production |

| ANSI API 5L/ISO 3183 | L290 or X42 –

L555 or X80 |

| API 5CT | from H40 to Q125* (except for L80 9Cr and 13Cr) | Production of Casing and Compressor Pump Pipes |

| GOST 632 | Steels of all strength groups |

| EN 10210-1 | S235JRH, S275JOH, S275J2H, S355JOH, S355J2H, S355K2H, S355NH, S355NLH, S460NH, S460NLH | Production of general purpose pipes for pipelines and steel structures |

| EN 10208-1 | L219GA, L235GA, L245GA, L290GA, L210GA |

| EN 10305-1,

EN 10294-1, EN 10297-1 | E275, E355, 20MnV6, 25CrMo4, 34CrMo4, E470, E420J2, E460K2, E590K2, E235 |

| EN 10216-2 | P195GH, P235GH, P265GH, 16Mo3 |

| EN 10216-1 | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| Standard | Steel Grades |

| ANSI API 5L/ISO 3183

ASTM A53

ASTM A106 | A, B, C |

| ANSI API 5L/ISO 3183 | L290 or X42 –

L555 or X80 |

| Standard | Steel Grades |

| API 5CT | від Н40 до Q125* (за винятком L80 9Cr та 13Сr) |

| GOST 632 | Steels of all strength groups |

| Standard | Steel Grades |

| EN 10210-1 | S235JRH, S275JOH, S275J2H, S355JOH, S355J2H, S355K2H, S355NH, S355NLH, S460NH, S460NLH |

| EN 10208-1 | L219GA, L235GA, L245GA, L290GA, L210GA |

| EN 10305-1,

EN 10294-1,

EN 10297-1 | E275, E355, 20MnV6, 25CrMo4, 34CrMo4, E470, E420J2, E460K2, E590K2, E235 |

| EN 10216-2 | P195GH, P235GH, P265GH, 16Mo3 |

| EN 10216-1 | P195TR1, P195TR2, P235TR1, P235TR2,

P265TR1, P265TR2 |

Round steel billets for further production of wheels, bands, axles and wheelsets for freight and passenger railway transport.

| EN 13262 | ER6, ER7, ER8, ER9

and their analogues | Production of All-Rolled Wheels |

| BS 5892 (part 2) |

| AAR M 107/208 | A, B, C |

| GOST 10791 | Steel 2, Т |

| UIC 810-1 | В2, В3, В5, В6 | Band Production |

| GOST 398 | Steel 2 |

| EN 13261 | EA1N | Axle Production |

| AAR M 101 | F |

| GOST 4728 | OC |

| Standard | Steel Grades |

| EN 13262 | ER6, ER7, ER8, ER9

and their analogues |

| BS 5892 (part 2) |

| AAR M 107/208 | A, B, C |

| GOST 10791 | Steel 2, Т |

| Standard | Steel Grades |

| UIC 810-1 | В2, В3, В5, В6 |

| GOST 398 | Steel 2 |

| Standard | Steel Grades |

| EN 13261 | EA1N |

| AAR M 101 | F |

| GOST 4728 | OC |

Round steel billets for further production of steel forgings, machine-building and automotive spare parts.

| ASTM A350 | LF2 and their analogues | Steel Forgings Mechanical Engineering & Automotive Components |

| ASTM A29 | 4130, 4140 and their analogues |

| EN 10025-2 | S235JR, S235J0, S235J2, S275JR, S275J0, S275J2, S355JR, S355J0, S355J2, S355K2 |

| EN 10025-3 | S275N, S355NL, S355N, S355NL |

| EN 10083-2 | C35E, C45E, C45 |

| EN 10083-3 | 34CrMo4, 34CrNiMo6, 25CrMo4, 42CrMo4 |

| EN 10084 | 18CrNiMo7-6 and their analogues |

| EN 10210 | 30CrMo4 |

| DIN 17200 | Ck60 |

| GOST 1050 | Steel Grades 10, 20, 35, 45 |

| GOST 19281 | 09G2S, 15GS, 17GS, 17GS1, etc. |

| GOST 4543 | 15G, 35G, 30HMA, 30HGSA, 10G2, 30G2 |

| GOST 14959 | 65G, 70 |

| Standard | Steel Grades |

| ASTM A350 | LF2 and their analogues |

| ASTM A29 | 4130, 4140 and their analogues |

| EN 10025-2 | S235JR, S235J0, S235J2, S275JR, S275J0, S275J2, S355JR, S355J0, S355J2, S355K2 |

| EN 10025-3 | S275N, S355NL, S355N, S355NL |

| EN 10083-2 | C35E, C45E, C45 |

| EN 10083-3 | 34CrMo4, 34CrNiMo6, 25CrMo4, 42CrMo4 |

| EN 10084 | 18CrNiMo7-6 and their analogues |

| EN 10210 | 30CrMo4 |

| DIN 17200 | Ck60 |

| ГОСТ 1050 | Steel Grades 10, 20, 35, 45 |

| GOST 19281 | 09G2S, 15GS, 17GS, 17GS1 |

| GOST 4543 | 15G, 35G, 30HMA, 30HGSA, 10G2, 30G2 |

| GOST 14959 | 65G, 70 |