Interpipe is one of the leaders in industrial sector decarbonisation in Ukraine and Europe.

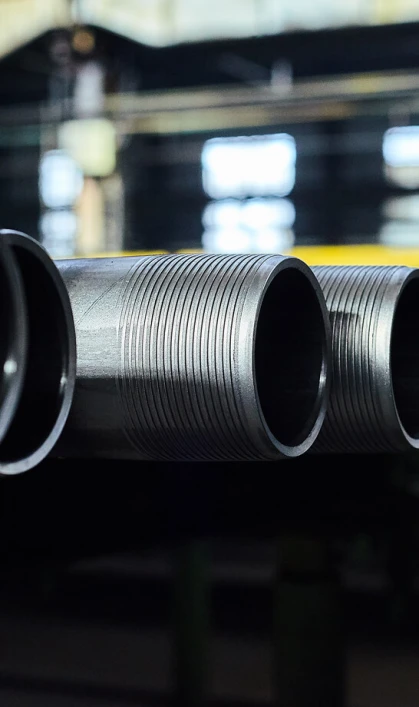

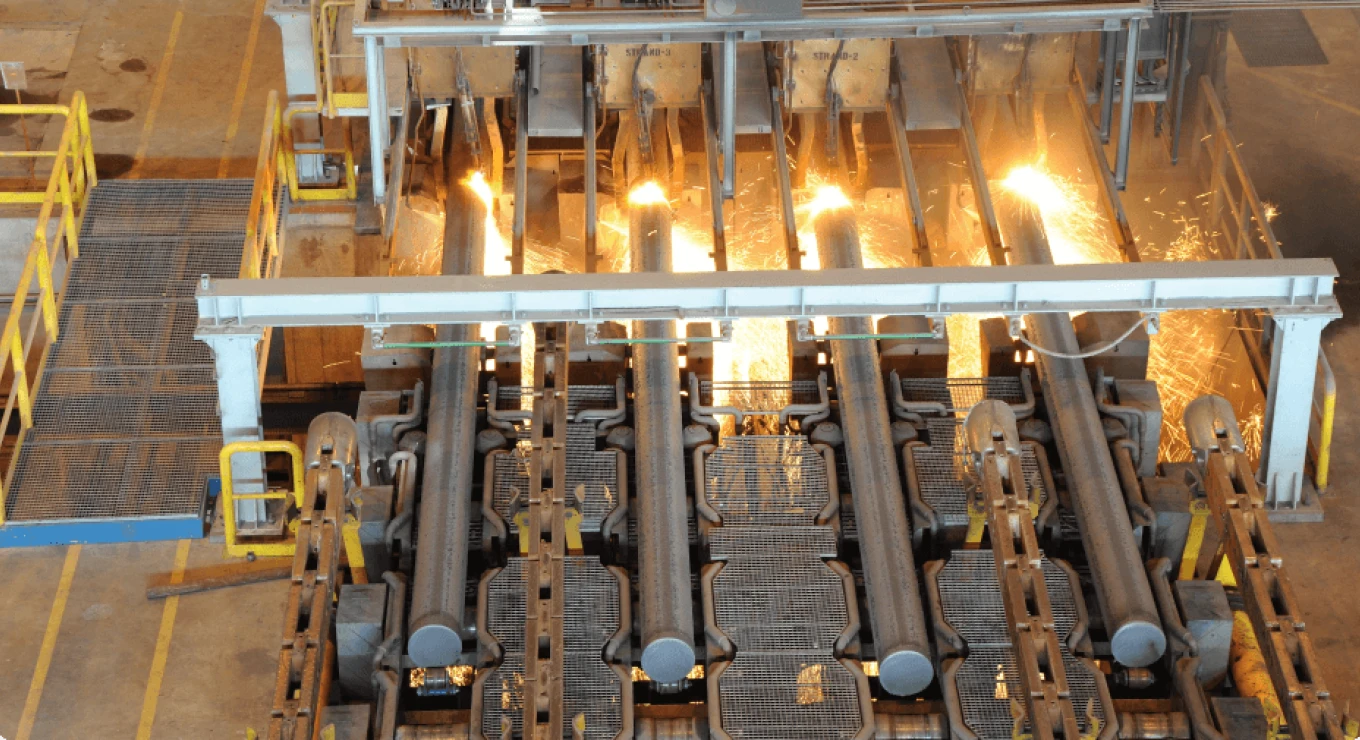

Back in the early 2010s, after the closure of a dirty open-hearth steel production, the Company launched its innovative electric steel-melting complex Interpipe Steel in accordance with the most stringent environmental requirements of the European Union. This is the largest environmental investment in the Ukrainian industry since the country's independence, totalling about $1 billion.