Fire extinguishing systems for metro stations in Riyadh, KSA

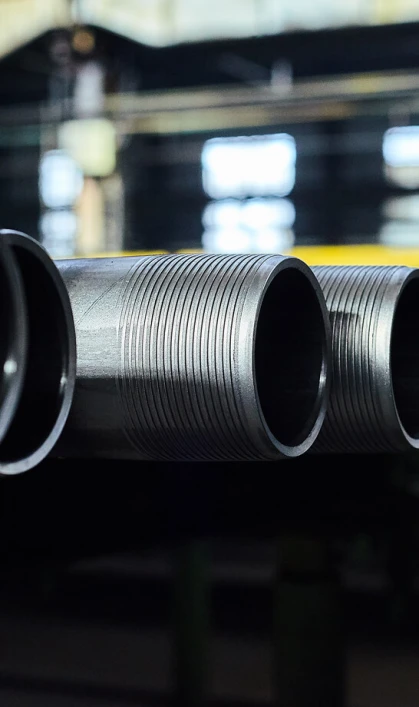

Tubular products

Energy Industry Solutions Mechanical Engineering Solutions Pipes for construction and general use Manufacturing Tubular Products Network of warehouses in Ukraine Customer Community Marketing Materials & Catalogues Projects Contacts (tubular products) Certificates

"Interpipe Niko Tube" LLC (Nikopol) Certificates

"Interpipe Niko Tube" LLC (Dnipro) Certificates JSC INTERPIPE NMPP

"Interpipe Niko Tube" LLC (Nikopol) Certificates

"Interpipe Niko Tube" LLC (Dnipro) Certificates JSC INTERPIPE NMPP

Tubular products

Energy Industry Solutions Mechanical Engineering Solutions Pipes for construction and general use Manufacturing Tubular Products Network of warehouses in Ukraine Customer Community Marketing Materials & Catalogues Projects Contacts (tubular products) Certificates

"Interpipe Niko Tube" LLC (Nikopol) Certificates

"Interpipe Niko Tube" LLC (Dnipro) Certificates JSC INTERPIPE NMPP

"Interpipe Niko Tube" LLC (Nikopol) Certificates

"Interpipe Niko Tube" LLC (Dnipro) Certificates JSC INTERPIPE NMPP

Main Tubular products

Tubular products

Projects

Pipes with a UPJ-F connection for oil wells, Turkey

Profile pipes for Expo-2020 pavilions in Dubai

Pipes for air conditioning systems for Hamad Airport, Qatar

Spare parts for heavy mining equipment, Germany

Cooling systems for the King Abdullah Financial District, KSA

Development of gas wells at the Krasnokutske field, Ukraine

Air conditioning pipes in Etihad skyscrapers, UAE

Boiler pipes for geothermal power plants, Hungary

Pipes with a UPJ-M connection for wells in Nigeria

Air conditioning pipes at the Al Janoub Stadium, Qatar

Intrepid SP casing pipes for the Permian Basin, USA

Air conditioning pipes for the Yas Marina Circuit race venue, UAE

Mine support structure, Ukraine