Interpipe is one of the leaders in industrial sector decarbonisation in Ukraine and Europe.

We started fighting climate change and reducing CO2 emissions before the early 2010s, when we decided to close down our dirty open-hearth steel production. In 2012, Interpipe launched an innovative electric steel-melting complex that has minimal greenhouse gas emissions.

Interpipe Steel is the largest environmental investment in the Ukrainian industry since the country's independence, worth around $1 billion.

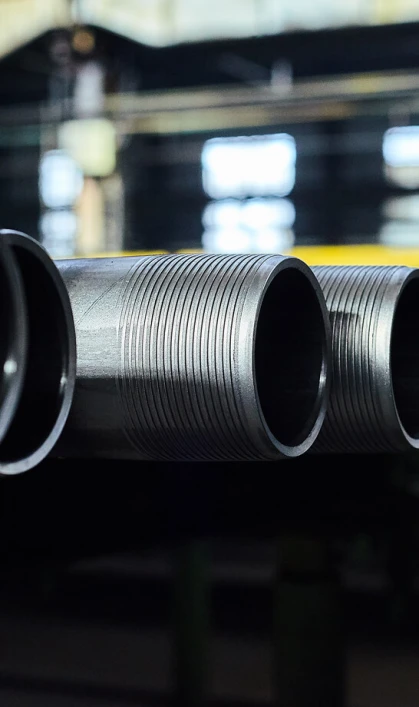

Built in accordance with the most stringent environmental requirements of the European Union, Interpipe Steel's electric steel-melting complex is a true flagship of green metallurgy in Ukraine. With emissions of less than 300 kg of CO2 per tonne of steel, our plant is among the best in the European steel industry in this respect.

Currently, out of the 3 known steelmaking technologies, only electrometallurgy allows us to meet the standards of the European Green Deal, which aims to reduce greenhouse gas emissions by 55% by 2030. The launch of Interpipe Steel to replace the outdated, environmentally unfriendly open-hearth production reduced CO2 emissions by 10 times, natural gas consumption by 8 times and harmful substances by 2.5 times.

From then onwards, every investment project of the Company has always had an environmental component. For example, further reduction of CO2 and other harmful substance emissions, waste management and improving energy efficiency at production.

Currently, our CO2 emission reduction rates are already exceeding the European Green Deal targets for 2030.

The main factors contributing to our low carbon footprint are our own electric steel production, using scrap metal as the main raw material for decarbonisation and the use of low-carbon electricity.